In Mold Labeling System

In Mold Labeling System

Comprehensively introduce the knowledge of in mold labeling, which is widely used in high-end technology for plastic food packaging.

| 1.1 IML Robot System |

|---|

| 1.2 In-Mold Labeling Mould |

| 1.3 In-Mold Labeling Injection Molding Machine |

| 1.4 In-Mold Labeling Plastic Film |

| 2IML (In-Mold Labeling) System |

| 2.1 IML Technical Difficulties |

| 2.2 Quality points of IML film |

| 2.3 Key points of IML mold technology |

| 2.4 Requirements for IML injection molding machines |

| 2.5 IML Technical Personnel Training Methods |

| 2.6 IML workshop production environment |

| 2.7 Future Development Trends of IML |

| 3. IML system classification |

| 3.1 Yogurt Box IML System Production Line |

| 3.2 Ice Cream Cup IML Production Line |

| 3.3 Milk Tea Cup IML Production Line |

| 3.4 Butter Packaging IML Production Line |

| 3.5 Paint Bucket IML Production Line |

| 3.6 Extrusion Blow Molding IML System |

| 4. IML product image |

| 5. IML related video display |

| 6. Auto Labeling System |

| 7. Automatic Label in Mould Technology |

What's In-Mold Labeling?

In mold labeling (IML) is an automated process that embeds pre printed labels into the surface of plastic products during injection molding. The label is combined with molten plastic to become an integral part of the product.

The Main Unit of In-Mold Labeling System

In-Mold Labeling Robot System

Robot is the arm of the In mold labeling IML system, responsible for accurately picking up and placing labels.

Its main components include

Label Pick up Head

Thin and lightweight labels are typically picked up using vacuum suction cups or electrostatic suction systems.

Motion control system

Mostly multi axis servo robotic arms, ensuring high-speed and high-precision placement of labels into predetermined positions within the mold cavity.

Visual system (optional)

Used to detect whether the label is present, whether the position is correct, and whether there are errors on both sides, ensuring the yield rate.

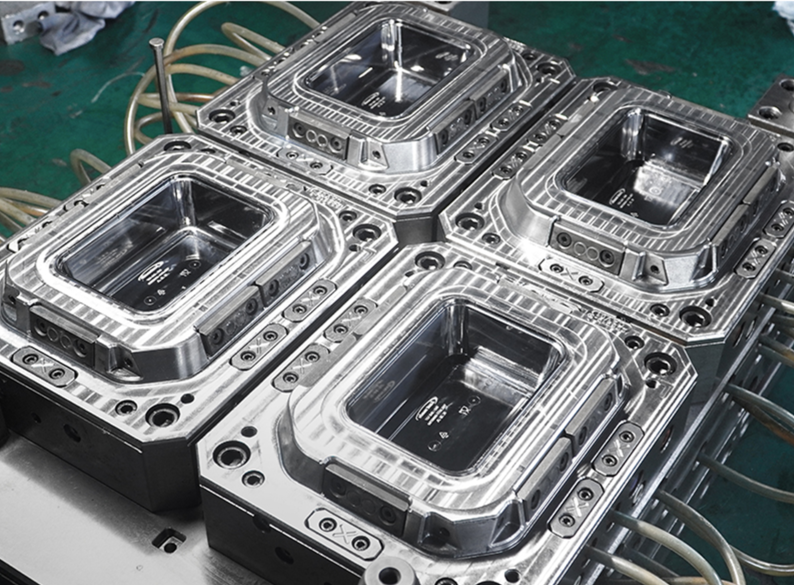

In-Mold Labeling Mold

The mold needs to be specially designed for IML process, There is a label fixing design on the mold, which requires electrostatic adsorption in addition to mold fixing.

Most of the in mold labeling molds are thin-walled molds. There are high requirements for the precision of mold dimensions, balance of hot runner, and cavities air venting and cooling system of the mold, and a professional mold company is needed to do a good job in this type of in-mold labeling mold.

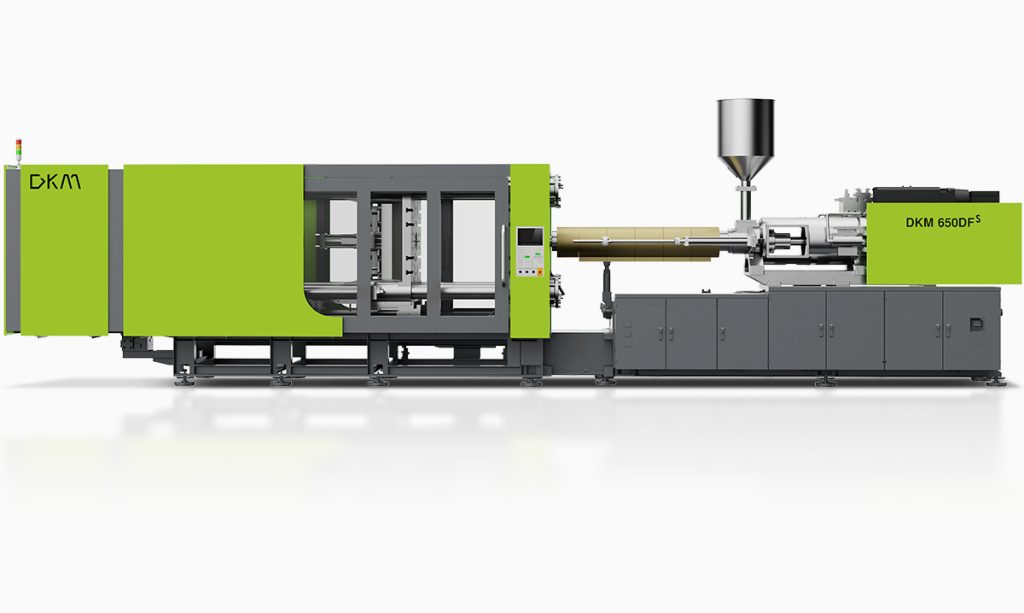

High Speed Injection Molding Machine

The injection molding machine required for in mold labeling is a high-speed injection molding machine, which requires the following characteristics:

Workflow of In-Mold Labeling

Pick The Label

The robotic arm moves to the label case position and uses a suction cup to pick up a pre punched label.

Label Place

The robotic arm accurately places the label into the opened mold cavity. The vacuum suction hole on the mold is activated to secure the label.

Mold Closing &. Injection

The mold is closed and molten plastic is injected into the mold cavity at high speed. The enormous pressure and high temperature cause the back of the label to melt and firmly bond with the melted resin.

Cooling &. Mold Opening

After the product is cooled and shaped in the mold, the mold is opened.

Ejection&Deflashing

A robotic arm or ejector system takes out the finished product. Sometimes a simple step may be required to remove fine nozzle material.

Next Cycle

The robotic arm returns to prepare to take the next label, and the entire process is fully automated in a very short cycle (usually a few seconds to a dozen seconds).

In-Mold Labeling Main Advantages

High quality appearance

Clear patterns, wear-resistant, scratch resistant, labels with the same lifespan as the product, no risk of warping or falling off.

Good tactile sensation

The surface is smooth and flat, integrated with the product, without the protrusion and edge feeling of traditional labels.

Great design freedom

It can achieve 360 ° panoramic decoration, transparent window effect (such as the visible margin of a shampoo bottle), and even tactile texture (frosted, velvety).

Efficient and environmentally friendly

No need for subsequent labeling processes, saving manpower and time. Usually, a single material PP label is used to facilitate the overall recycling of the product.

Good anti-counterfeiting

The process is complex and difficult to replicate.

Challenges &. limitations of In-Mold Labeling

- High initial investment

Requires specialized molds, robotic arms, and peripheral equipment, with costs much higher than traditional labeling. - Complex process

Extremely high requirements are placed on mold design, precision of robotic arms, and control of production processes (temperature, pressure, time, etc.). - High label cost

Requires customized printing and punching. - Suitable for mass production

The cost advantage of a single piece can only be reflected in mass production, which is not suitable for the production mode of small batches and multiple varieties.

IML(In-Mold Labeling) compare to IMD (in-mold decoration)

This is a concept that is easily confused. It can usually be understood as follows:

IML (In Mold Labeling):

mainly refers to the decoration of flat or simple curved surfaces, with the final label located below the surface of the finished product. Commonly found in food packaging boxes, barrels, basins, etc.

IMD (In Mold Decoration):

It is a broader concept that encompasses more technologies, such as:

IMF (In Mold Film):

Used for decorating complex three-dimensional surfaces, the film can completely wrap around the three-dimensional structure of the product. Commonly seen in car interior panels, home appliance control panels, etc.

IMR (In Mold Transfer Printing):

The pattern layer of the label will be transferred from the carrier film to the surface of the product during the molding process, and the carrier film will be peeled off and recycled. After completion, there is no additional film layer on the surface of the product.

Simply put, IML in mold labeling is a specific form of IMD technology.

In-Mold Labeling Main Applications

Food packaging

ice cream bucket, yogurt cup, butter box, fast food container (which is its largest application market).

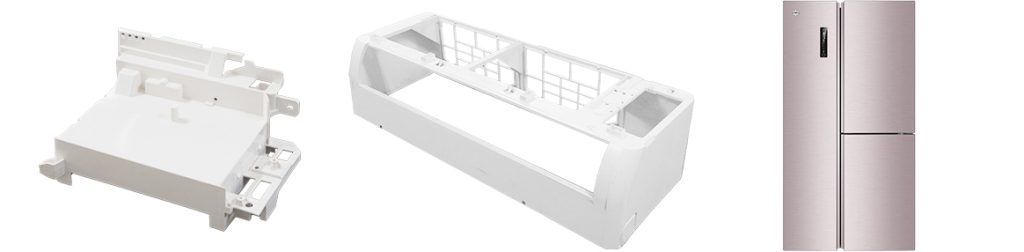

Daily household appliances

washing machine panel, microwave button panel, air conditioning display window, rice cooker shell.

Automotive components

interior trim, control buttons, dashboard trim.

Electronic products

Exterior components for refrigerators, air conditioners, and some small household appliances

Summary of In-Mold Labeling Technology

The In Mold Labeling (IML) system is a high-end automated manufacturing technology that integrates precision robotic arms, special printing labels, and specialized molds. It achieves a one-step completion of decoration and molding, endowing plastic products with excellent appearance, texture, and durability. Although the initial investment and process threshold are high, its quality advantage and comprehensive cost-effectiveness in mass production make it the preferred decoration solution for many high-end plastic product brand.