In-mold labeling (IML) robots place labels into the mold before injection, bonding them to the part during molding. This approach is ideal for thin-wall packaging and other high-speed applications. Suppliers such as IVIROBOT offer complete solutions, including injection molding machines, IML-dedicated machines, molds, and auxiliary equipment.

Core Components of an IML Robot System

- Stacking and pick-place unit: Organizes labels and parts, and synchronizes loading/unloading with the mold cycle.

- Label feeder and clamp: Delivers labels consistently and holds them with high positional accuracy across different sizes and materials.

- Vacuum circuit: Applies controlled vacuum to secure labels to the cavity surface quickly and reliably.

- Collection and conveyor: Sorts, collects, and transfers finished parts and scrap for inspection and packing.

- Control system: Interfaces with the molding machine to coordinate label placement, injection, cooling, and demolding in each cycle.

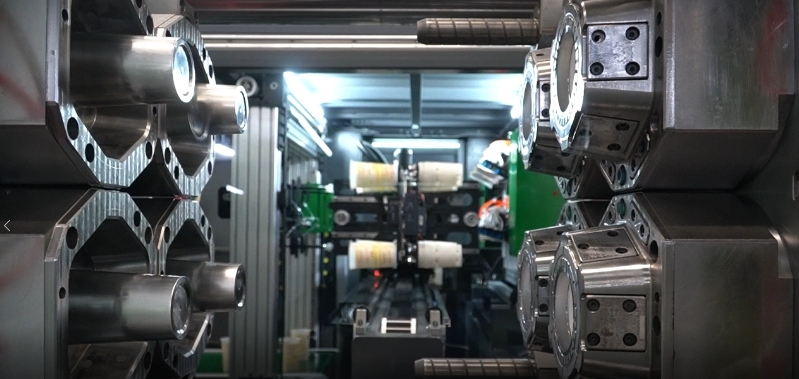

Robot Architecture and Motion

- End-effector (hand): Custom grippers and suction tools are tailored to the part’s shape, size, weight, and material, ensuring safe handling of labels and molded parts.

- Motion system: Linear and rotary axes provide fast, repeatable movements for label insertion and part removal, supporting single- and multi-cavity molds and multi-station layouts.

Benefits of IML Robots

- Higher throughput: Optimized for thin-wall cycles to cut cycle time and increase capacity.

- Better appearance and durability: Labels become part of the molded surface, offering abrasion, moisture, and chemical resistance with sharp graphics.

- Lower total cost: Reduces secondary labeling and manual handling, cutting labor and defects.

- Quick changeovers: Rapid swaps of end-effectors and label magazines for short setup times.

- Compact footprint: Space-efficient designs integrate easily into existing lines.

- Data and traceability: Works with vision, sensors, and MES for quality control and tracking.

Industry Trends

IML robots are becoming more compact, faster, stiffer, and more precise. Improved mechanics and smarter controls raise dynamic performance, stabilize cycles, and boost first-pass yield.

System Configuration and Selection

IVIROBOT supplies complete IML robot configurations. Systems can be specified by part size, cavity count, label type, target cycle time, and automation level, covering label loading, in-mold placement, molding, take-out, sorting, and conveying. For specifications and recommendations, contact IVIROBOT for a consultation.