IML (In-Mold Adhesive) System: A comprehensive analysis: a technical guide from principle to application

I. Basic concepts and definitions of IML system

IML (In-Mold Labeling) is an advanced manufacturing process where pre-printed labels are embedded into plastic molds, achieving seamless integration with the material. This technology is primarily used in blow-molded and injection-molded products made from materials like PP, PE, and PET. By inserting pre-printed labels into the mold cavity before blow-molding or injection-molding, the high-temperature and high-pressure conditions ensure complete fusion between the labels and the plastic substrate.

The IML label adopts a three-layer composite structure design:

Print layer: Top layer for printing patterns and text Main

body layer: Middle layer to provide structural strength and shape stability

Hot melt adhesive layer: Bottom layer that melts with plastic substrate under high temperature and pressure

Compared with traditional label technology, IML technology has strong anti-counterfeiting, wear and scratch resistance, environmental protection and recyclability and other significant advantages, and has become the preferred solution for high-end product packaging and decoration.

II. Working principle and process of IML system

1. Core working principles

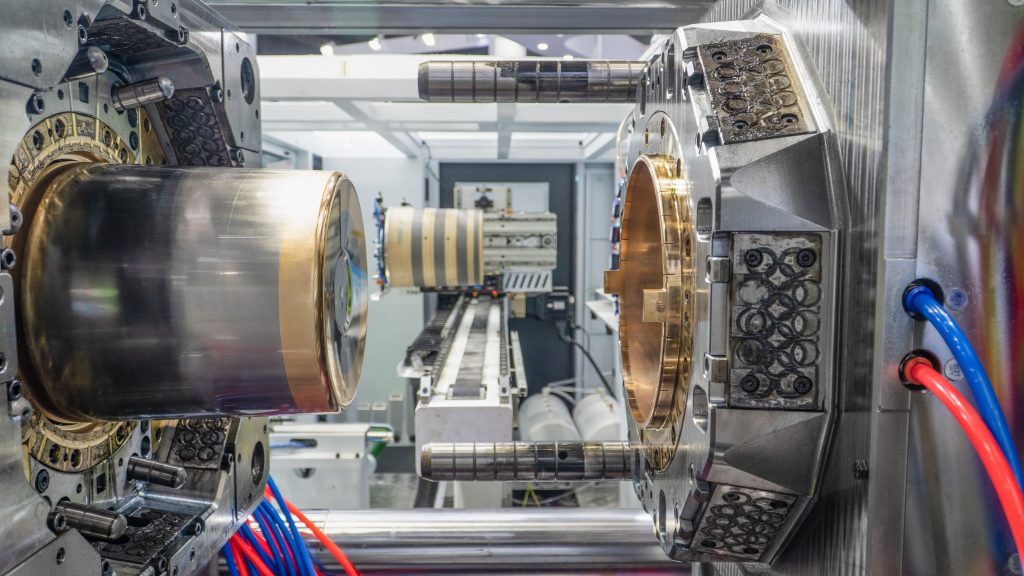

The IML process is a process in which a patterned film (thickness 0.08-0.3mm) is precisely embedded into an injection mold and integrated with a plastic substrate (such as PC, ABS) under high temperature and high pressure. The key processes include:

Labeling: The electrostatic treated film label is accurately positioned into the mold cavity by the robot, and the positioning accuracy should reach ±0.1mm

Melt fusion: The molten plastic is injected into the mold at a high temperature of 140-180℃, and the label adhesive is formed into a molecular level bond with the plastic substrate

Synchronous molding: after plastic cooling and curing, the label and the surface of the product are completely integrated to form a seamless decorative effect

2. Detailed process flow

- Cutting: Cut the roll of film into square blocks of the desired size

- Flat printing: Using a film screen to print graphics and text on a film

- Ink drying: Fix printing ink in a high temperature oven

- Apply protective film: prevent damage to printing surface in subsequent processes

- Rip positioning: Ensure accurate positioning of thermoforming and shearing processes

- Thermal forming: the film is pre-shaped by hot pressing to make it conform to the product surface

- Injection molding: The robotic arm feeds the pre-shaped film into the mold and injects molten plastic

- Post-deformation treatment: the product is directly formed after demolding without secondary processing

III. Application fields of IML system

IML technology has been widely used in many industries due to its excellent performance and aesthetic effect:

- Consumer electronics industry

- Home appliance industry

- automotive industry

- Food packaging industry

IV. Advantages and features of IML system

IML technology has several significant advantages over traditional labels and decorative processes:

1. Appearance and durability advantages

High aesthetic degree: the label is seamlessly integrated with the product surface, and special effects such as laser and aluminum plating can be presented

Wear-resistant: the surface hardness can reach more than 3H, far beyond the traditional spraying process

Good weather resistance: waterproof, oilproof, mold-proof, adapt to a variety of environmental conditions

2. Production and environmental advantages

High production efficiency: a single injection molding cycle is only 15-30 seconds, suitable for mass production

Cost effective: The overall cost is lower than traditional labels and direct screen printing

Environmentally recyclable: The label and container can be crushed and reused together without secondary pollution

3. Functional and safety advantages

Strong anti-counterfeiting: complex process, difficult to copy

Health and safety: eliminate the risk of contamination from secondary printing and labeling

Comfortable touch: smooth surface without seams, good user experience

V. IML Technology Development Trends

IML technology is developing rapidly in the direction of material innovation, intelligent production and environmental protection:

1. Material innovation

Biobased film: biodegradable PLA material reduces carbon emissions by 60%

Functional films: Graphene conductive films achieve self-healing surfaces

Optical film: Micro lens array to achieve naked eye 3D effect

2. Intelligent manufacturing

AI quality control: defect rate reduced from 2% to less than 0.1%

Flexible production line: the change time is reduced to 15 minutes

3. Green manufacturing

Ultra-thin injection molding: product thickness reduced to 0.5mm, weight reduced by 40%

Water-based inks: VOC emissions reduced by 90%

Solvent free bonding: avoid the harm of benzene solvents

VI. Comparison of IML with other technologies

IML technology has unique advantages compared with traditional label technology and similar in-mold decoration technology:

Type of technology | Process characteristics | applicable scene | Main advantages | boundedness |

IML | The label is fully embedded in the product | High durability requirements products | Wear-resistant, anti-counterfeiting, environmental protection | High development costs |

IMR | Transfer and peel off the carrier film | Large quantities of flat products | Low cost, bright colors | Wear resistance is normal |

pressure-sensitive adhesive | Label later | Various packaging containers | Simple process, low cost | Easy to peel, not environmentally friendly |

Direct screen printing | Print directly on the surface of the container | Simple pattern products | Cost effective | Color is monotonous, not wear-resistant |

IML is particularly suitable for high-end consumer goods, automotive parts and medical equipment where decorative effects and durability are required, while IMR is more suitable for mass production of flat products such as home appliance panels.

Summary

As a revolutionary innovation in plastic decoration, IML in-mold labeling technology is reshaping product appearance design standards with its exceptional durability, exquisite decorative effects, and eco-friendly features. With advancements in material science and smart manufacturing, IML technology will demonstrate its value across more high-end sectors, unlocking endless possibilities for product innovation. For companies pursuing quality and differentiation, mastering IML’s technical characteristics and applying them appropriately will become a crucial pathway to enhance product competitiveness.